With the mission of promoting the development of the pharmaceutical industry, SEN Pharma always encourages businesses to focus on improving the quality system. Unfortunately, many companies do not pay enough attention to quality, resulting in long-lasting errors that can affect the effectiveness and safety of medicinal products.

During an FDA conference in September 2022, Donald Ashley, director of the Office of Compliance, presented a specific case where a company repeatedly had quality-related problems but failed to tackle them completely.

The mentioned company is Morton Grove, owned by Wockhardt (India). This factory is located in Illinois and specializes in producing OTC and generic drugs. The FDA has inspected this factory several times. The inspection in 2016 found the following violations:

- Inadequate investigations for OSS result (OSS – Out of specification)

- Tests are repeated until the results meet the standard

- Inadequate validation process

- Numerous concerns with data integrity

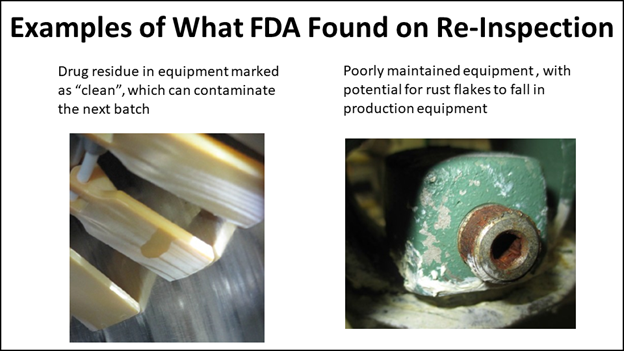

These problems have been repeated over the years with no discernible improvement. Even some issues, such as data integrity, worsened during inspections in 2019 and 2021. One particular example is that backdating of microbial test results was overlooked by the facility manager, which brought concerns about the reliability of the test results. Another example is inadequate procedures to prevent cross-contamination. Traces of powder residue or equipment rust have been observed, and there is a risk of direct product contamination in production.

These errors are so severe that the Department of Justice has to be involved, leading to a court order in 2022. According to this ruling, the factory must “stop production, processing, pasting label, store, or distribute substandard products. In addition, the factory must destroy all drugs on site, except those that are therapeutically necessary.” Until now, most of the corporation’s factories must have received a warning letter from the FDA and have been put on the U.S. Import alert or stopped operating in the U.S.

So what is the cause of the repetition of this error?

- Poor quality culture is believed to be a major cause of these recurring errors. Similar violations are even observed in other manufacturing sites.

- Weakness in leadership. Inspectors deemed it a significant factor in not addressing errors thoroughly or even worsening errors despite warnings from the FDA, such as data integrity issues.

This case is a reminder for businesses to invest properly in building a culture of quality, starting with commitment from the leaders of the enterprises, and setting an example for the whole company to follow.

REFERENCES:

Persistent Non-Compliance Leads to a Consent Decree