1. Chemical structure

Povidone, also known as polyvinylpyrrolidone (PVP) or polyvidone, is a water-soluble synthetic polymer composed of the monomer N-vinylpyrrolidone.

2. Pharmacopoeial nomenclature

Povidone (USP, EP, JP).

3. Trade name

- Povidone; Polyvidone; Polyvinylpyrrolidone; Poly[1-(2-oxo-1-pyrrolidinyl)ethylene]; 1-Vinyl-2-Pyrrolidinone Polymer; E1201; POVIPHARM®; Kollidon® Povidone; PLASDONE™.

- Manufacturer: BASF, Asland, JRS Pharma, JH Nanhang, Shanghai Yuking Water Soluble Material Tech Co., Ltd.

4. Classification

Povidone is classified into many grades based on the degree of polymerization, which is indicated by the K value. The greater the K value, the greater the degree of polymerization, and the greater the viscosity and molecular weight of povidone. the greater the adhesiveness. Current K values consist of the following grades: K12, K15, K17, K25, K30, K60, K90, and K120.

- BASF is the leading manufacturer of povidone under the brand name Kollidon®, including the following grades: Kollidon® K12, Kollidon® K17, Kollidon K25, Kollidon® 30, Kollidon® 90, and Kollidon® K17PF.

- Povidone Asland is marketed under the brand name Plasdone and is available in the following grades: PlasdoneTM K12, PlasdoneTM K17, PlasdoneTM K25, PlasdoneTM K29/32, and PlasdoneTM 90.

- JRS Pharma manufactures three grades, namely Vivapharm® PVP K25, Vivapharm® PVP K30, and Vivapharm® PVP K90.

Appearance: The aforementioned grades all come in the form of a fine powder that is white to off-white and almost odorless. Grades with K values less than or equal to 30 are spray-dried and spherical. Povidone K90 or greater is produced using the “drum drying” technique, resulting in a flat (plate) form.

5. Physicochemical properties

- pH ranging from 3.0 to 7.0 (5% in water).

- Melting temperature of approximately 150 degrees Celsius; High hygroscopicity.

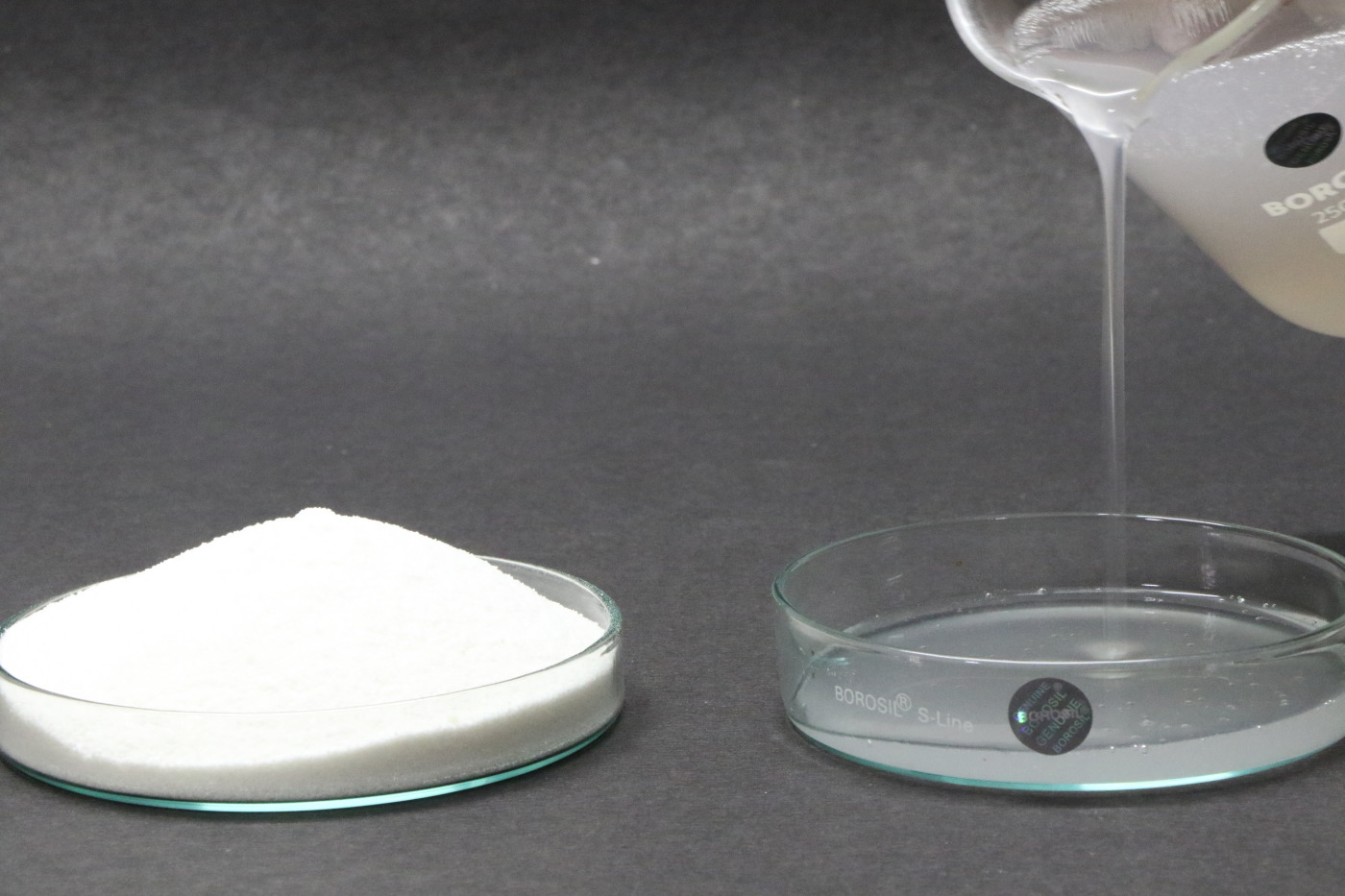

- Solubility: soluble in water, ethanol (95%), acids, and IPA.

- Viscosity is determined by K value, typically ranging between 1.2 and 2.5 mPa s (10% Povidone K12) and 300 and 700 mPa s (10% Povidone K90).

6. Main application

Povidone is mentioned in the most common pharmacopeias USP-NF, EP, JP, and is included in the US FDA database as an excipient used in most dosage forms such as IM and IV injections, eye drops, and capsules, tablets, suspension, sublingual tablets, topical and vaginal formulations.

Povidone is a common excipient in the pharmaceutical industry, serving a number of the following purposes:

- Binding for capsules and tablets

- Forming suspension

- Increasing solubility

- Creating solid dispersions, or polymers in the hot melt extrusion method

- Creating matrix structure

Povidone is also employed as a tablet thickener, viscosity enhancer, suspension agent, and film-forming agent. The primary use of povidone in solid dosage form is as an adhesive excipient for wet granulation, dry granulation, and direct compression. The most frequently used grade is K30 povidone.

7. Using Povidone in wet granulation method

In the wet granulation method, povidone is typically used between 1 and 10 percent of the formula, depending on the grade. At a concentration of 10% in water or in ethanol 95%, IPA, povidone forms a viscous solution.

Alternatively, povidone can be added directly to the dry powder mixture and then granulated by adding water or ethanol. This method requires a higher amount of Povidone K30, usually greater than 5% due to its weaker granulation ability.

Or you can also mix a part of povidone directly into the dry powder mixture, the remaining part is mixed with the above mixture to create granules. This method is employed when the amount of solvent in the formulation is limited.

8. Selecting the correct grade

Povidone with a low molecular weight (Povidone K12, K15, and K17) produces low viscosity and adhesion, making it suitable for formulations where compressibility and tablet hardness are not crucial parameters, such as capsules. In contrast, when greater compression and hardness are required, > 8% of this grade should be used.

- Povidone K25 and K30 provide a balance between three factors: adhesion, hardness and disintegration, so they are commonly used. Povidone K30 is the most suitable grade for creating solid dispersion systems by the hot melt extrusion method.

- Povidone K90 is a suitable binder for tablets with a high API/tablet ratio and poor compressibility. The amount of povidone K90 used in tablets is from 1 – 2%.

- When preparing povidone as a viscous solution, add each portion of povidone K30 to the solvent and vigorously stir to ensure that the povidone dissolves completely and does not clump.

- Only Povidone K17PF, K25, K30, and K90 are mentioned by the Japanese Pharmacopoeia.