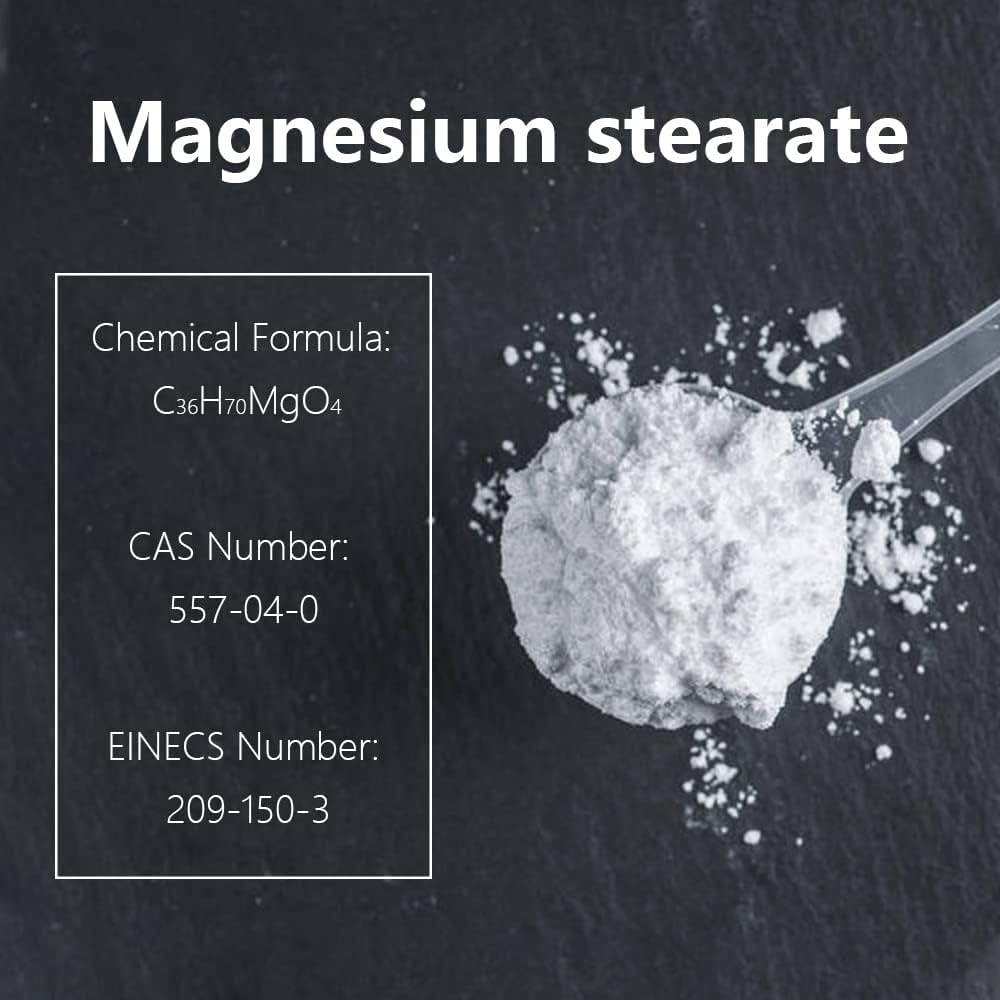

1. Chemical structure

Ester of magnesium and stearic acid, derived from plant origin.

2. Pharmaceutical nomenclature

Magnesium stearate (BP, JP, PhEur, USP NF).

3. Trade name

HI-MAST, Magnesium stearate, Roquette Magnesium Stearate.

4. General properties

White fine powder, mild odor; soluble in oil, slightly soluble in ether, alcohol, benzene, and hot 95% ethanol; insoluble in water.

5. Incompatibility

Magnesium stearate and strong acids and iron salts are incompatible. Avoid mixing Magnesium stearate with ingredients that have oxidizing properties during production. In addition, products containing aspirin, certain vitamins, and the vast majority of alkaloid salts should not contain this excipient.

6. Main application

- Magnesium stearate is primarily used as a lubricant in the production of tablets and capsules at concentrations ranging from 0.25% to 5.0% w/w. Due to its relatively low friction coefficient and large covering ability, magnesium stearate is the most popular anti-adhesive excipient. MgSt reduces friction between powders and mortar/pestle walls during compression of tablets, capsules, and powders. Furthermore, due to its water-insoluble nature,

- Magnesium stearate can create a smooth and waterproof coating on the skin’s surface in the cosmetics industry, keeping the skin dry.

7. Personal experience

- Magnesium stearate is insoluble in water and can therefore affect both solubility and tablet hardness; therefore, the lowest concentration is typically recommended for formulations containing this excipient.

- When mixing powder and granules with magnesium stearate, the mixing time is an important factor in addition to the its ratio in the formula. During the mixing process, MgSt can form a covering other excipients and granules. Long mixing times can result in the phenomenon of “over blending/over mixing,” which increases drug release time, decreases tablet hardness, and lengthens tablet disintegration time. MgSt adsorbs onto the grain surface before distributing uniformly across the grain surface. A study reveals that MgSt can be uniformly distributed on the surface of granules within a short mixing time. Even when mixed for a brief period of time, MgSt demonstrates excellent anti-sticking properties, as demonstrated by the rapid decrease in tablet ejection force.

REFERENCES:

- Evaluation of the Impact of the Concentration and Mixing Time of Magnesium Stearate in Tablet Formulations – A Design of Experiment (DOE) Approach

- Handbook of Pharmaceutical Excipients Fifth Edition.

- Magnesium stearate, a widely-used food additive, exhibits a lack of in vitro and in vivo genotoxic potential